Types Of Chiller System

"*" indicates required fields

Types Of Chiller System in KL & Selangor

The chiller system in the HVAC (heating, ventilation, air conditioning) system removes heat from a liquid through a vapour compression or absorption refrigeration cycle, then, it is circulated through a heat exchanger (evaporator heat exchanger or condenser heat exchanger) to cool equipment or other stream (air or water processed). The condenser heat exchanger forms the major component in rejecting and transfer the heat from the chiller to the atmosphere.

However, this level of performance can only be sustainable with the systems well maintained, including its chillers being one of its critical components to be handled by qualified air conditioners professionals who are experts in this field which can also be those providing services in facilities management involving air conditioners and chillers for the commercial and industrial sectors. In well maintained systems which undergo regularly in the various process of facilities management running through its checklist for all parameters that will affect the overall performance of the systems and so thus its efficiency when it is in operations.

From the results of each parameter checked, it is able to determine which parameters or components that require rectifications such as replacement of respective parts or servicing the affected components, such as the filters, condenser coils, evaporator coils, etc. Through this process once completed the cycles in a good order usually will prolong its performance in an efficient manner and will lower its electric consumption with savings whilst running the systems.

As you may imagine, there are many different types of chillers categorised by its types and one way to categorised them is by defining them into 2 types :

- Vapour Compression Chiller

- Vapour Absorption Chiller

Vapour Compression Chillers use electrical-driven mechanical compressors forcing the refrigerants within the systems and this is the most common types of chillers which is sub-categorised into two vapour compression chillers i.e. air-cooled chillers and water-cooled chillers. However, both these types of air-cooled and water-cooled chillers have the same basic vital components: evaporator, compressor, condenser and expansion valve.

Nevertheless, both refers to the same basic working principle whereby the compressor pushes the refrigerant inside the chiller between the condenser, expansion valve, evaporator and back to the compressor with the only difference being the air cooled chiller, its fan forcing air across the exposed tubes of the condensers that carries away the heat, whilst in the water cooled chiller, it has a sealed condenser and water is pumped through it taking the heat away and dispersing it through the cooling towers which also uses a fan to reject any unwanted heat out of the system.

Vapor systems normally temperature control systems using in large capacity. It is typically designed to compress low pressure into high in their main components. Industry requirements moves engineering of controller selection for the efficiency of operation cost.

Let us presumed the cooling tower is located at the top of an office building. The ‘condenser water’ is moved by the centrifugal pump between the chiller in the basement and the cooling towers on its roof with the chiller adding heat to this condenser water, whilst the cooling tower’s cooling it by way of ejection of this heat into the air. This heat ejected is all the heats within the building derived from the lighting, computers, sunlight, people, etc. as well as the heat produced by the chiller’s compressor.

Usually, the temperature of this condenser water in the chiller will be at about 32°C when the pump pushes it up its cooling towers and the system was designed such that this condenser water that leaves the cooling tower, returned-back into the chiller’s condenser at about 27°C so as to enable it to pick-up sufficient heat on its next cycle.

On the other hand, Vapour Absorption Chillers use heat source to move the refrigerant within the system and the refrigerant in these chillers moving around within the system between the areas of different pressure and temperature. This type of chiller is recommended to be used as and when there is abundance of high quality waste heat or cheap heat.

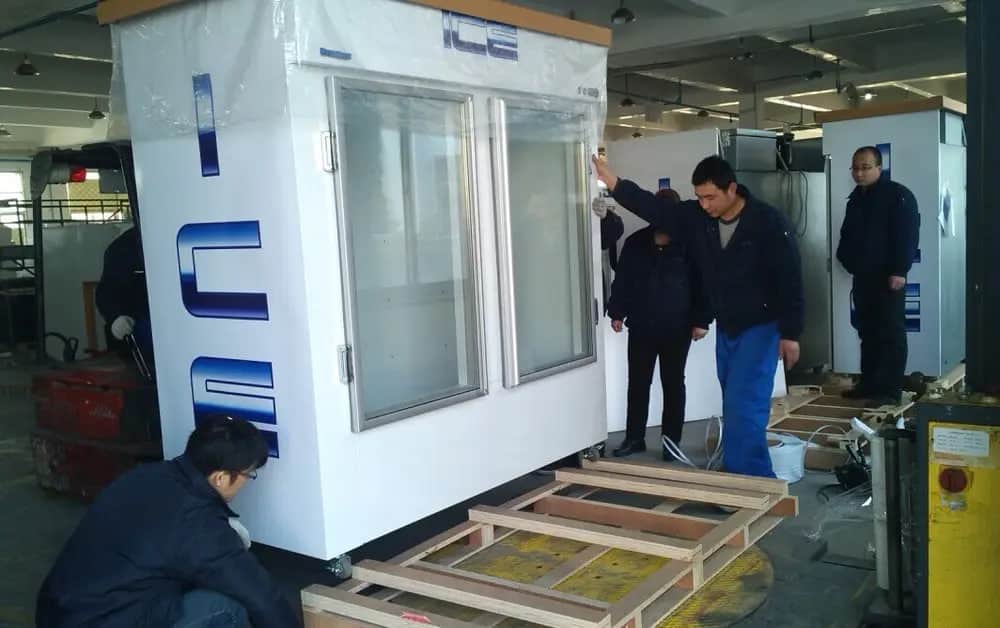

We, as a professional chiller system service provider in Kuala Lumpur and Selangor offer a wide range of chiller maintenance services, etc. that suits your needs for your facility. Other than that we also install and repair air conditioners as well as provide air conditioning systems services and we take care as well as handle for all your air condition unit needs within the established industry work standards and monitoring of its performance, it need not necessarily have to be an expensive affair.

Please call us or Whatsapp us today for a quotation and advice with solutions to your air conditioning systems, including the chillers at affordable cost.

Services

Aircon Installation

Chiller Repair

Aircon Servicing

Chiller Servicing

Aircon Repair

Freezer Repair

Aircon Trade In

Freezer Servicing

Why Us?

Professional Technician At Your Doorstep

Our technicians are professionally trained

Free Site Survey

On site survey at no cost

100% Customer Satisfaction

We aim to deliver the BEST for you

Testimonials

Their technicians were very helpful, courteous, updating us on the job progress frequently and very communicative. This was my third time using their services and they are real professionals. I am extremely satisfied with their performance all this while and they are courteous. I will recommend them to others.

Your team’s response time was superbly fast! The details on the problem of my air conditioner were well explained to us and subsequently it was rectified. Then, your team proposed to us for a maintenance plan that I immediately agreed. In future, I wouldn’t have to call anyone else for such jobs except them!

With the complete and thorough job by your team in your recent inspection and maintenance schedule the other day, we were indeed very satisfied with their performance. So happen they also discovered a problem with the air cond and after recommending to us whom we agreed, it was done beautifully indeed.

The service provided was superb and the response was excellent! I couldn’t be any happier with such a fantastic servicing rendered to us by your team of experts and their promptness really is a plus plus point. The service is simply the best in this area; no one else can match them. Kudos to your team!

I had some issues with my air conditioner leaking on a Saturday and we felt great the service techs who came and repaired it on the spot. He was doing such an excellent job, explaining to me on the things to be done. In a matter of hours, our air conditioner was back to normal. They did such a fantastic job!

Great and fantastic service indeed! They have sent 3 men team of professional technicians to service my 4 units of air conditioners in my condo. They did a thorough inspection on the air conditioners whilst servicing them and they have tidied up my place after they completed the job. Surely we will recommend them to others.

Contact Us For A Free Consultation Now!

Handphone:

"*" indicates required fields